2007 Winners

Winners in the Building Category

Pavilion in the Park

David

Miller,

Seattle,

WA, Architectural Designer at The Miller|Hull Partnership

Category: Building—Professional Built

The 11,100 square foot Pavilion in the Park’s entire structure is designed for future transportation, reassembly and reuse in a new location. The building’s parts separate at three integrated joints to break into four separate modules that can be moved on trucks by surface street. The building sits lightly on the land atop short concrete piers allowing the grade and vegetation to run uninterrupted beneath. Gangway ramps with integrated hinged joints, allow the ramps to adapt to the topography of future locations.

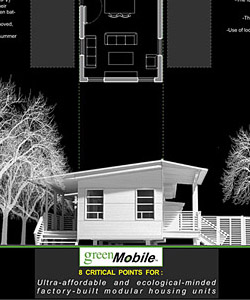

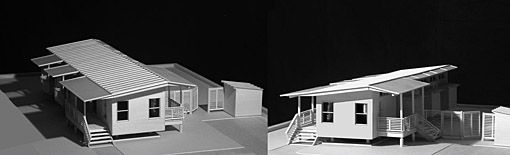

GreenMobile™

Michael Berk, Mississippi State, MS—Professor at Mississippi State University School of Architecture

Category: Building—Professional Unbuilt

The GreenMobile™ envisions affordable, factory-built energy efficient mobile home units that meet International Residential Code for housing with structurally-sound foundations, demountable for easy relocation, and can function in a place with a limited infrastructure or no utility grid in-place. They can be used for immediate disaster relief housing (including first responders) and later converted to permanent housing. This project will incorporate systematic strategies for growth and change as family structures also grow and change. "Pre-fabricated plug-in" rooms, plug-in porches, and surface mounted wiring are also featured in this design.

groHome

Adam Fenner, Jason Bond, Thomas Gerhardt, Josh Canez, Nick Schaider

College Station, TX—A team of students at Texas A&M University, 2007 Solar Decathlon Team

Category: Building—Student

The open source concept used in the software community is adapted in this entry to develop open source building systems allowing anyone to design and incorporate elements into the building system if grid protocols and standard joint connections are used. Using a library of pre-manufactured components brought to a site and assembled efficiently, the structure is designed with a specialized bolted connector joints that allows for components to be unplugged easily and without damage. Radio Frequency Identification Tags (RFID) can be embedded to take inventory and check the history of components. The project even includes a community building game, Utopia 2.0, to allow neighbors to swap building modules as family and community needs change.

Winners in the Component Category

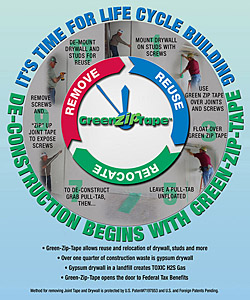

Demountable Tape

Frank Little Magnolia, TX—Founder of Tax Advantage Design

Category: Component—Professional Built

This patented demountable tape provides an alternative method for hanging sheetrock for later de-construction and reuse. Drywall has traditionally been a barrier to gaining easy access to structural components of the building for repair or reuse. This tape and associated screw connectors allow drywall to be easily removed and replaces the traditional nailing mechanism, which can damage the drywall and inhibit reuse.

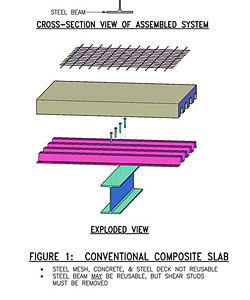

Deconstructable and Reusable Composite Slab

Mark D. Webster, Dirk M. Kestner, James C. Parker, Matthew H. Johnson Waltham, MA—Structural Engineers at Simpson Gumpertz & Heger, Inc.

Category: Component—Professional Unbuilt

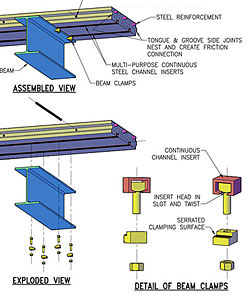

The composite component system uses specialized bolts, serrated clamps, and cast-in channels to create a more easily disassembled system, allowing reuse of the composite slab. A serious problem with the conventional composite slab is that it is a "throw-away" system; most of the parts are completely non-reusable at the end of the building's life. The team developed a composite slab system that maintains the efficiency benefits offered by composite action, while adding near 100 percent reusability. This structure allows the slab and beam to work together to resist bending due to floor loads. The size of the steel beam can be reduced by over 30% providing both economic and environmental benefits.

Guidelines for Building with Reusable Materials

Aaron Tvrdy Lincoln, NE—University of Nebraska

Category: Component—Student

This project foresees waste materials gathered in bulk, refurbished, and stored in regional design centers where designers can create components out of the former waste. One example uses discarded railroad track and ties to create a superstructure for a wood pallet wall system. With a creative design approach, reclaimed material kits can be used to create attractive components that can either celebrate or conceal their original identity.

Winners in the Service Category

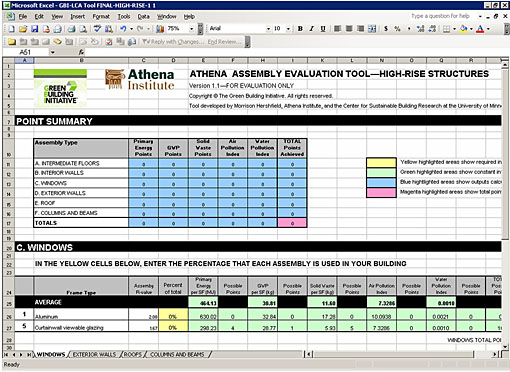

ATHENA Assembly Evaluation Tool

Wayne Trusty Kutztown, PA—The ATHENA Institute

Category: Service—Professional Built

Life Cycle Analysis (LCA) is one tool for determining the environmental impacts of various building materials through all phases of its life, from extraction through use and disposal. The ATHENA software tool adopts LCA methodology to measure the climate-changing potential and other environmental impacts of more than 400 common building assemblies. A generic version will be made available, free of charge, to the entire sustainable construction community.

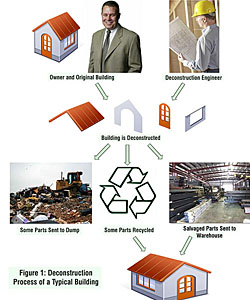

Deconstruction Engineer

Keith Cullum, Paul Sargent San Luis Obispo, CA—California Polytechnic State University

Category: Service—Student

The project proposes a new degree program and profession: the deconstruction engineer. These professionals would consult throughout a building’s lifecycle to ensure that adaptation and deconstruction occur in the most effective way. During the first stages of planning a structure, the engineer would offer design suggestions to anticipate efficient deconstruction and at the end of a building’s life, the deconstruction engineer would evaluate and assess safe reverse construction procedures for salvaging materials.

People's Choice Award Winner

Sustainability by Design: Deconstruction and Adaptive Reuse

Chuck Otto Holland, MI—Haworth

Category: Building—Professional Unbuilt

When Haworth, a global designer and manufacturer of adaptable workspace environments, planned major renovations on its headquarters, the company set a goal to recycle or salvage up to 75 percent of the materials. The project diverted more than 99 percent of construction materials through reuse and recycling: 321 tons of steel were recycled; 75 workstations were donated; and even the door locksets were removed intact and reused in other facilities. More than 58,000 tons of carpet tiles were removed for re-installation, donation to local schools, or recycling.